En-Masse Grain Drag Conveyors for Efficient Grain Handling

En-Masse Grain Conveyors

Dense-phase transport for zero spillage & max efficiency. High-quality en-masse chain drag systems manufactured in-house. Built for heavy-duty grain handling with fast delivery across the USA.

En-Masse Conveyor Models

Our en-masse systems use advanced drag-chain technology for seamless, enclosed grain flow — perfect for high-volume farms and commercial grain handling.

Why choose our en-masse grain conveyors?

High Capacity

Capacities from 3,000 to 15,000 BPH for commercial and farm-scale operations

Durable Construction

Heavy-duty galvanized steel construction with enclosed design to reduce dust and grain damage

Custom Solutions

Custom lengths from 20 to 100 ft, including horizontal, inclined, and vertical configurations

Nationwide Service

Made in South Dakota, shipped nationwide — ideal for corn, soy, wheat, and abrasive grains

Efficient Transport

Dense-phase conveying minimizes spillage and energy use (up to 30% less than belt systems)

Low Maintenance

Drag-chain technology with minimal wear for long-term reliability

How En-Masse Conveyors Work

En-masse (or drag-chain) conveyors move grain in a dense "plug" formation using a continuous chain with flights. This enclosed system ensures gentle handling, low dust emission, and high throughput — perfect for tight spaces or high-volume transfers from field to bin.

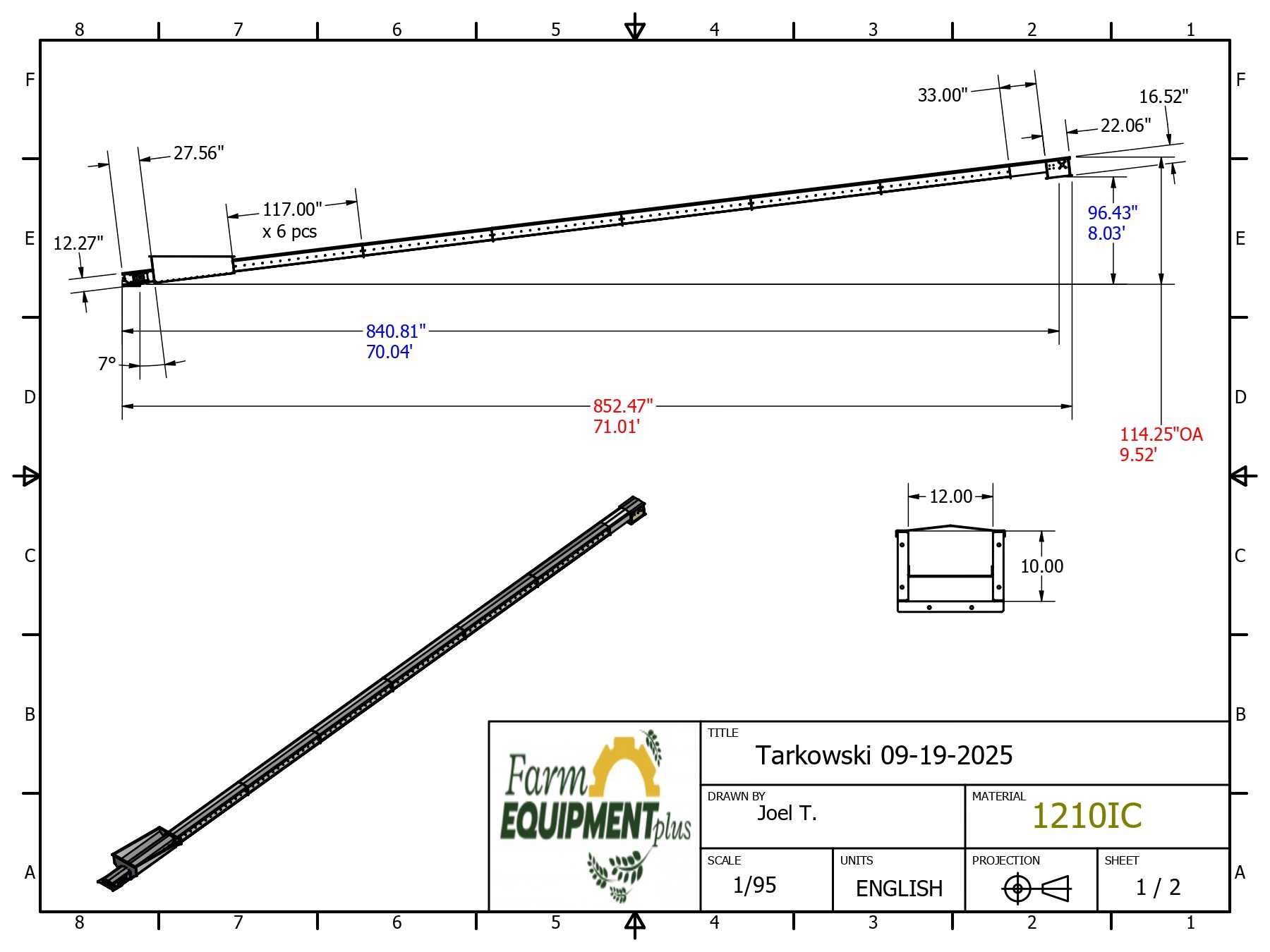

47′ en-masse conveyor, model 1210 — horizontal transfer.

Real Farm Results

Iowa Corn Farm Upgrade

John D., Iowa: "Switched to Model 1610 en-masse — increased throughput by 40% with zero dust issues. Installation was a breeze, and FEP's support was top-notch."

Capacity boost: 6,000 BPH • ROI in one season.

Nebraska Soybean Operation

Sarah L., Nebraska: "Model 1214 handled our 7,500 BPH soy flow perfectly on a 7° incline. Custom length fit our bin layout exactly — saved us thousands in downtime."

Energy savings: 25% vs. old belt system.

Shipping & Financing

We ship across the USA from South Dakota. Typical lead times: 2–4 weeks for standard builds, 4–6 weeks for custom. Flatbed and LTL options available. Export to Canada: Duties included in quote; 6–8 week lead for international.

- Nationwide in-house financing for qualifying customers

- 2-year warranty support and wide selection of spare parts

- Free phone support for installation, layout questions, and troubleshooting

Grain conveyor on videoWatch how simple our conveyors are

Watch how simple to use our conveyors